Ultrasonic welding technology for plastics

Ultrasonic

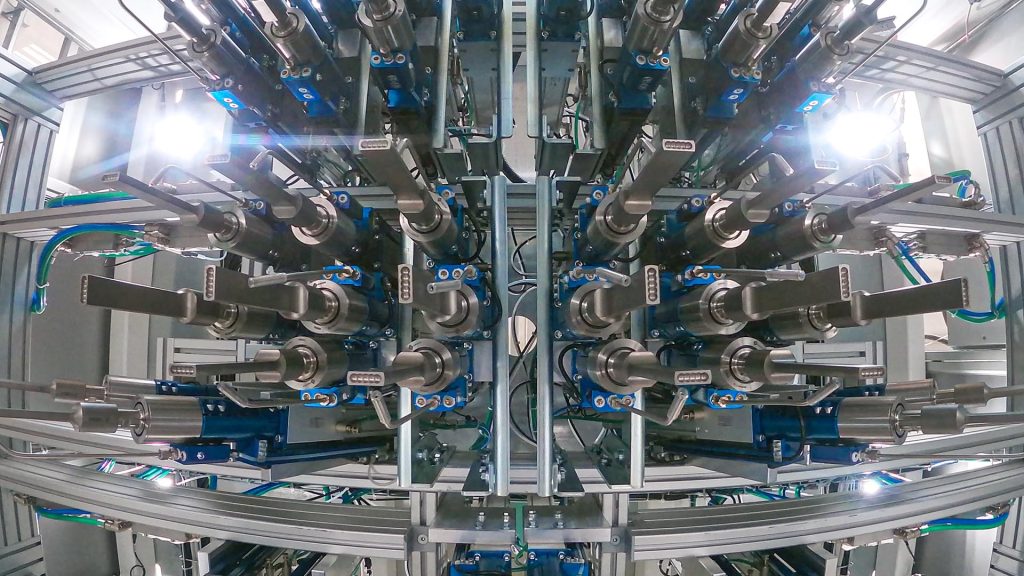

Ultrasonic Welding is the fastest and most versatile of all welding processes.

The Ultrasonic Welding, be it with rivets or direct welding, is the joint of components via heating generated by a high-frequency mechanical motion. In case of riveting, only one component melts thus it is not necessary for the other component to be thermoplastic. In case of direct welding, the friction energy of the sonotrode transmits to both parts with pre-set values of pressure, time, and speed. The generated heat melts the thermoplastic components where they touch. The result is a cohesive welding between compatible materials. In both scenarios, the process is accomplished under a strict and meticulous control on the transmitted energy.

Welding

Hotplate

Hot Plate Welding Machines are parts of the EUROMODEL standard machinery. Thanks to decades of R&D, today we have a remarkable know-how related to this technology.

Hot-plate welding is the most suitable system for joining large components with even complex geometries. After cooling, the welding shows an excellent aesthetic quality and is characterized by a very resistant and watertight joint. This procedure allows to join elements that have a certain degree of dimensional tolerance. Virtually all thermoplastics can be welded together, despite different stiffness.

Welding

Laser

Since 2019 EUROMODEL has introduced diode and CO2 laser welding technology in its catalog: the most innovative and flexible machinery that we provide at your disposal.

In recent years, laser welding of thermoplastic materials has increasingly taken hold in the world of industrial applications that require rapid processes, good aesthetics, and thin welding profiles. Welds performed with diode and Co2 lasers add to traditional welding methods such as ultrasound, vibration, or hot blade welding. It provides all the advantages of non-contact welding, without forming filaments or burrs but the possibility of welding complex geometries. It also offers significant advantages and performance capabilities such as: precision, cleanliness, aesthetics, speed, and repetitiveness compared to traditional plastic welding methods.

CONTACTS

Get in touch

"*" indicates required fields

SONIC ITALIA SRL

Viale De Gasperi, 76

20017 Rho (MI)

info@sonicitalia.com

www.sonicitalia.com